Connector Redesign

The male half of a connector being used in a pump system was creating both assembly, molding, and aesthetic problems. Through multiple iterations, I was able to fully redesign the connector to improve in all of these problem areas.

Role / Designer

Date / Summer 2019

Skills / CAD modeling, Molding, Design thinking

Company / Equinox Opthalmic Inc.

The current connector design:

an assembly of 3 main parts with added tubing, creating an overall complicated, intricate assembly process. The design of the connector also created a complicated molding operation, adding time and cost to the manufacturing process.

The redesign:

create the connector from 2 parts, simplifying the tubing attachment process to both ease assembly and make the part more moldable. Make the connection of the two parts simple and clean, making it more visually appealing and simplifying the molds.

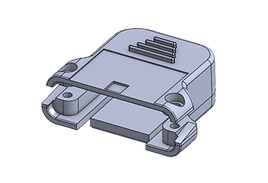

Rev A

Inserts preserved from original connector, since female half would not be changed. Latter half changed to incorporate barbs, middle divider for support, and cylinders for tubing attachment. Grip shape redesigned, working around the trapezoidal shape also kept from original connector. Screw holes adjusted for barbs.

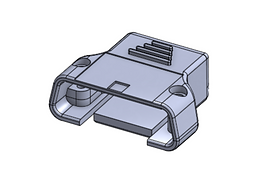

Rev B

Barbs shortened to accommodate smaller grip, divider removed on insert; grip shortened and inside supports added to replace divider on insert.

Rev C

Grip shape redesigned for better user experience, the small grip in Rev B proved hard to remove after insertion; barbs on insert lengthened for stability.

Rev D

Barbs incorporated into grip walls for easier assembly. Minor grip edits for aesthetic purposes.

Rev E

Barb and wall interlace sharpened. Drafting added for molding.